NOVEC REPLACEMENTS SOLUTION

W H Y are semiconductors so important to so many industries?

How Is a Semiconductor Manufactured?

What Is Semiconductor Manufacturing?

Transforming silicon and/or other raw materials into semiconductor devices is a complex process that can take months to complete. Semiconductor manufacturing is the fabrication method used to create integrated circuits (IC), consisting of transistors and other components that are built into modern electronic devices. The process is made up of multiple chemical and photographic processing steps that transform a wafer of semiconducting material into electronic circuits. What raw materials are needed for semiconductors? Typically, manufacturers use pure elements like silicon or germanium as semiconducting materials.

What Is Required for Semiconductor Manufacturing?

The fabrication process includes three main areas: wafer creation, circuit construction, and packaging. Below are the most essential components required in the process.

Raw Materials like silicon or compounds

Gases like nitrogen, oxygen, and argon to create the proper environment and chemical reactions to shape the semiconductor’s electrical properties

Semiconductor Manufacturing Equipment, including dicing machines, probing machines, edge shaping products, and grinders

Quality Control Equipment like optical inspection systems, to ensure product quality

Semiconductor Grinding, Lapping, & Polishing Systems

Stock Removal and Nano Grinding

By adopting a stock removal and or nano grinding approach, surface roughness figures of 2nm Ra can be achieved therefore facilitating the capability to go straight to CMP after grinding.

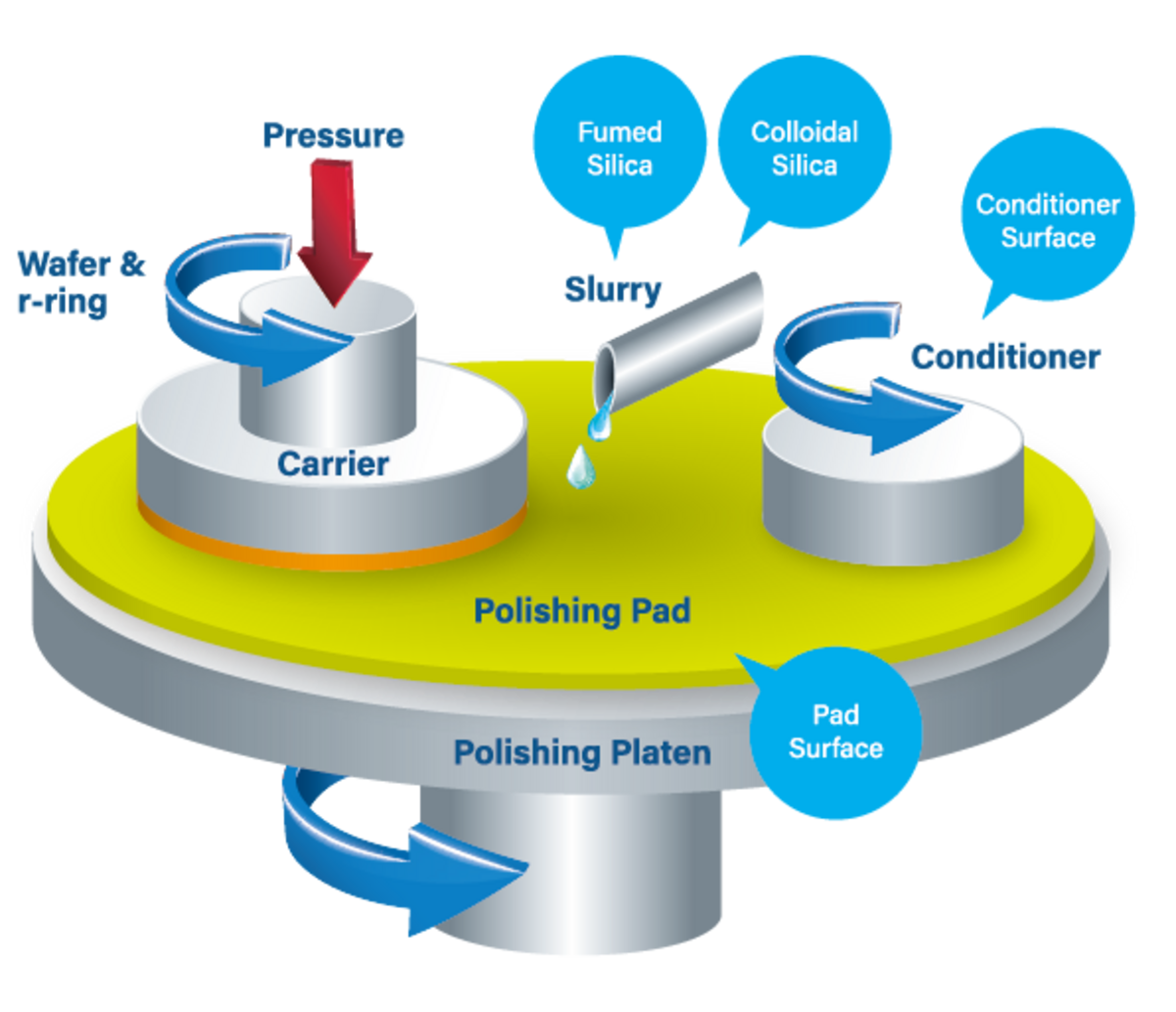

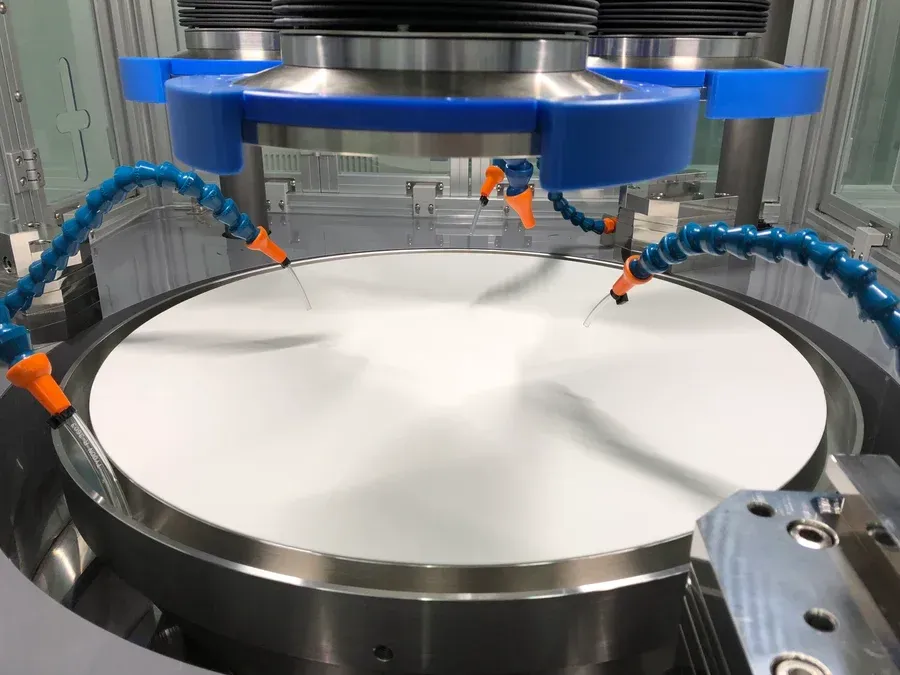

CMP Chemical Mechanical Polishing

Post-Grinding Engis offers specifically developed machines and consumable products capable of efficiently producing Epi surfaces on virtually all semiconductor materials.

Semiconductor Wafer Grinding & Back Thinning

- SiC

- Si

- AI203

- GaN

- GaAs

- InP

- AIN

- Others